Optimizing Meat Processing with the SD and Beluga®: The Future of Separating Technology

The meat processing industry is constantly evolving, and the need for high-quality separation technology has never been more important. It can be a complex and challenging industry, requiring the use of specialised equipment to separate meat and poultry products from raw materials in an efficient, sanitary, and cost-effective manner. …

Revolutionizing Safety in the Workplace: The BladeStop Bandsaw

The BladeStop bandsaw, developed by Scott Technology, is a game-changer in the world of bandsaw safety. Designed with operator safety in mind, bandsaws are known to be one of the most dangerous pieces of cutting equipment used in protein and industrial applications, with operator injuries and amputations being a common occurrence. The BladeStop bandsaw aims to reduce this risk by mechanically stopping the blade within a fraction of a second when it senses that the operator has come in contact with it. …

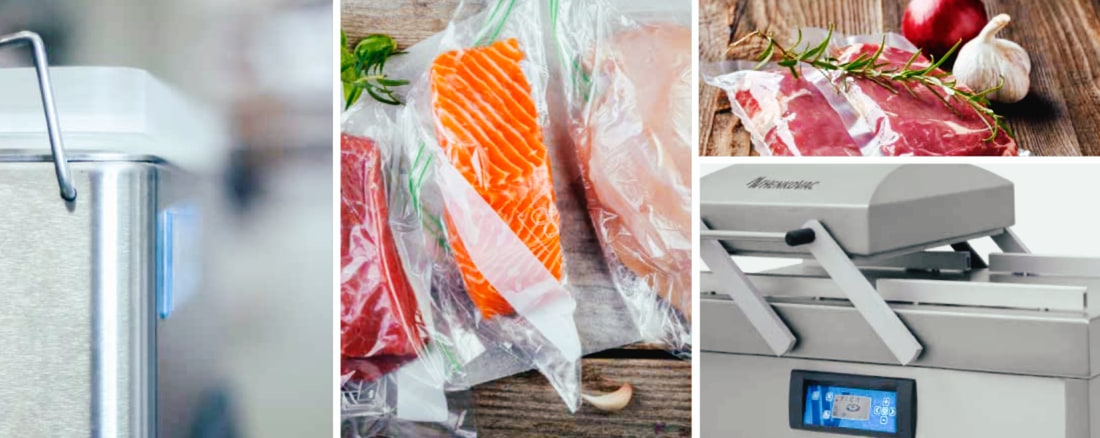

Henkovac: The Leading Choice for Vacuum Packaging Machines Among Professionals Worldwide

Henkovac is a leading manufacturer of vacuum packaging machines, based in The Netherlands. With almost 70 years of experience in the industry, the company has become a trusted source for professionals in the food and non-food packaging industry worldwide. With a wide range of equipment and a global network of dealers, Henkovac is the number one choice for companies in the food processing and preparation industry. …

Ollari & Conti: The Market Leader for Efficient and Compliant Processing of Animal Byproducts

In recent years, the need for efficient and compliant processing of animal byproducts has become increasingly important in the slaughter plant and food industries. Ollari & Conti International, established in the late 1960s by cousins Enzo Conti and Bruno Ollari in Parma, Italy, specializes in providing consulting, designing, and manufacturing services for machines that meet these needs. …

By 2026, the market for meat processing equipment will be worth $13 billion.

The global meat processing equipment market is forecasted to see substantial growth in the coming years, according to a report by The Business Research Company. The market is expected to increase from $9.78 billion in 2021 to $10.43 billion in 2022, and further to reach $13.62 billion by 2026 at a compound annual growth rate of 6.89%. …

Provisur Technologies introduces updated soft separators

Provisur Technologies, a leading manufacturer of industrial equipment for food processing, has expanded its new STS (Soft Tissue Separator) series of mechanical deboning separators to 4 modifications. …

The challenges of injection process

The precision of the injection and along with it the quality of the product mainly depend on the following factors: the brine composition and conveyance process and the composition of the piece of meat/fish. This problem is a challenging task for the manufacturers of injectors. …

SCHRÖDER IMAX HIGHline injectors

IMAX injection technology for highest demands The processing principle of the IMAX technology is based on classic injection curing by means of hollow needles. This is where know-how regarding needle type, inlet and exit holes and needle stitch pattern plays a decisive role. The brine/emulsion to be injected is carried directly to the product by a system of pumps and pipes. As well as boneless products, bone-in meat, poultry, and fish can also be injected. IMAX 420/520/620 – Walking beam injector For the IMAX walking beam injectors, the meat is transported through the machine via a transport rake. This follows …

Welcome To The World Of Fish Processing

Fish is an expensive and precious commodity. It is varied and challenging in its thermal treatment possibilities. Intelligent and expert drying and smoking is therefore a basic requirement for successful, flavoursome and visually attractive products. Ever more fish processing companies are therefore relying on one of our concepts in the production of smoked fish: …