Reich AIRMASTER ® UK SmokeHouses

The AIRMASTER® UK is a genuine all-rounder. It is distinguished by a very interesting price/performance ratio. UK universal systems can be supplied in all desired sizes from 1 to 14 trolleys with a one or two-row entranceway.

SKU:

Reich AIRMASTER® UKCategory:

Smoking chambersTags:

AIRMASTER® ATA CLIMASTAR, AIRMASTER® IC INTERCOOLER, AIRMASTER® KRAI CLIMASTAR, AIRMASTER® UK FISCH, AIRMASTER® UKQ AIRJET, climatic control, drying processes, efficiency, fish fillets, fish preservation, fish processing, fish smoking, fish treatment, food production, German engineering, horizontal airflow, hot smoking, hybrid processing, intensive cooling, Made in Germany, mechanical engineering, modular design, predictive maintenance, product defrosting, protein cook-out, quality assurance, real-time monitoring, REICH, REICH BlueConnect, REICH legacy, salmon processing, seafood innovation, seafood processing technology, smoking processes, state-of-the-art technology., taste engineering, thermal processes, thermal treatment, thermoprocessing, vertical airflowThe AIRMASTER® UK is a genuine all-rounder. It is distinguished by a very interesting price/performance ratio. UK universal systems can be supplied in all desired sizes from 1 to 14 trolleys with a one or two-row entranceway.

The application options range from drying, smoking, cooking and hot simmering through to baking. If desired, the AIRMASTER® UK can be supplied with appropriate special equipment for curing, climate-controlled smoking or even for high temperature baking and for cooling the cooked products. The AIRMASTER® UK is well suited for hanging products and also for products lying on racks if the batch concentration is adapted. Integrated fully automatic CIP cleaning is a matter of course.

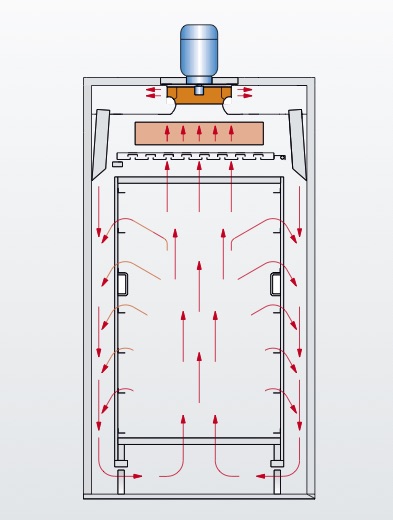

The AIRMASTER® UK operates on the proven vertical air circulation principle. The air prepared in the head section of the system flows through the products from bottom to top. A newly developed blowing system ensures that the products are evenly treated in all positions of the chamber trolley and thus in the shortest possible time.

Description

The AIRMASTER® UK installations are built as modular systems. Components such as control units, smoke generators or cleaning batteries can be individually arranged in accordance with your wishes or spatial circumstances.

The chamber housing of the AIRMASTER® UK consists of one or more chamber modules depending on type. Every chamber module is very stably constructed of 100 % chrome-nickel steel, material no. 1.4301, and welded to prevent leakage of smoke and steam. A full mineral insulation protects against heat loss. Importance was attached to the prevention of thermal bridges when developing the design.

The modules are screwed tightly together with a seal during assembly with the sealing surfaces being formed as stable angular structures. The air preparation unit is installed with a fan, heater and cooling unit in the head section of each chamber module. High quality products from German manufacturers are always used for the heavily stressed components such as motors, water and air valves, pneumatic cylinders etc.

Every AIRMASTER® has a durable chamber floor. Stress caused by heavily loaded chamber trolleys is no problem. Loading by industrial trucks is also possible for special designs. The floor structure is kept very flat and provided with a sloped ramp. The substructure of the chamber floor is reinforced with strong U-beams in the direction of travel.

Single and multiple trolley systems in a one-row design have fully insulated stable block board doors with a circumferential silicone seal to seal off the chamber housing. The locking elements and swivel joints are completely produced from chrome-nickel steel to meet the high demands on leak-tightness and long service life. The door hinge can be installed on the left or right as desired. Multi-trolley systems in two-row design are equipped with two block board doors.

Tightly sealing, metallic swivel dampers or rotary dampers with silicone rubber seals are used for fresh air, exhaust air and smoke flaps. These dampers have multi-functional settings for adjusting the volumetric flows. This allows for the versatility of the AIRMASTER® systems.

REICH SMOKE GENERATORS

SUITABLE FOR EVERY TASTE! The REICH systems produce little noise, but in return a great deal of good smoke.

The REICH smoke generators are the result of many years of development work. All of the smoke generators presented here are perfectly attuned to the AIRMASTER® series. The smoke generators operate fully automatically together with the REICH UNICONTROL control systems and their design and safety devices conform to the latest technology.

REICH CONTROL UNITS

PROGRAMMED FOR SUCCESS!

We at REICH offer the suitable control unit for every requirement and purpose.

The wealth of experience and suggestions of many customers have influenced the current controller generation of the UNICONTROL series. The result is the most user-friendly control system generation ever.

REICH SERVICE AND MAINTENANCE

Buying a thermal processing unit is a decision for most businesses, which has far reaching consequences. It usually represents a significant investment and you, as a customer, bind yourself to a partner for many years to come with its purchase. REICH’s service begins long before the purchase of a unit. We spend time with you, engage in talks and ascertain your individual requirements. Afterwards, we use the acquired information to create the best possible package and always think outside the box.

A team of our specialists and fitters who have been successfully practising their trade for many years is at your disposal during project realisation with delivery, assembly and commissioning. Our aim is for every customer, whether they be a large industrial company or small trade business, to feel like they are in good hands. Our work has been successful once we have achieved this aim.

After commissioning, we offer our customers an extremely attractive maintenance offer, which is unique to the market in this form. We can produce an individual maintenance plan for the customer and unit, which covers all eventualities when operating a REICH unit.