Yield control

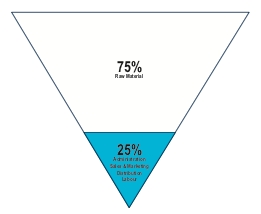

Yield has a significant, direct impact on the bottom line. Since 70-75% of the cost of the final product stems from the raw material, it is vital to closely control the actual yield against the expected.

Taking the guessing out of processing

Yield has a significant, direct impact on the bottom line. Since 70-75% of the cost of the final product stems from the raw material, it is vital to closely control the actual yield against the expected.

Even very small deviations in percentages between the actual and the expected yield can have a substantial financial impact on the profitability of the business because of the ever increasing tonnages being processed.

Monitoring and controlling profitability

Profit margins are under pressure

• Small mistakes triggers red figures

• Implementing IT for process control and automation is an necessity

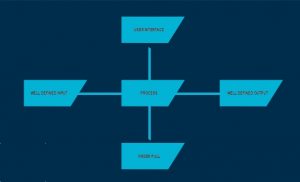

Logical process areas determines how the yield system works

• Configurable production flow

• Paths between processes

• Yield points for data collection

• Well defined ins and outs

• Measures product paths

• Built-in reports

• Scalable processes

• Supports a wide range of scales and devices

Recipe based yield control for deboning and cut up tasks

Recipe describes how a product is transformed into other products.

Process:

• An operator receives a product

• Based on the recipe the product is processed and transformed into one or more products

Each of those products has:

• An expected yield

• An actual yield

• A +/- balance