Further meat processing

Equipment and solutions for production of sausages or convenience products.

With our forming, coating, cooking and frying systems, you’ll be able to achieve further processed product results with highest quality and yield.

Meat preparation

The frozen blocks are cut up either by top knife (guillotining) or by two cutting rollers (roller knives) at possible working temperatures of -5°C to -25°C for further processing in the cutter, mincer or mixer.

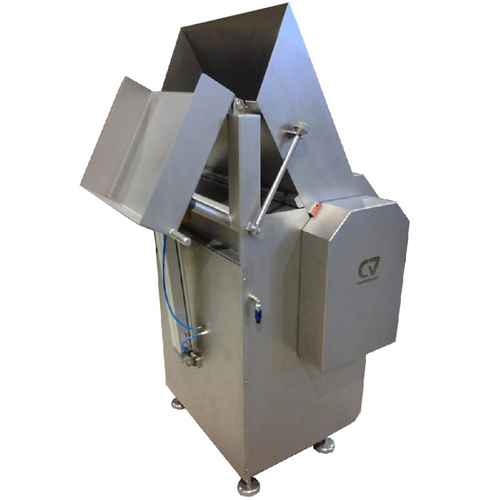

Small capacity

Semi-automatic meat mincers for small and medium production. Meat Mincers for hygienic and economic meat processing machines, saves time and money and achieves the best results during the mincing of high-quality products.

Medium capacity

The automatic mixer grinders from are offering the optimal solution for all types of superior-quality size reduction. Due to the optimisation of the screw geometry and the screw housing and due to the use of new materials, Our grinders achieve top results with peak output from 1.000 up to 3.000 kg/h in best quality.

Industrial grinders

Professional machines for the ambitious food processing industry.

High-performance models with a processing capacity from 5.000 to 36.000 kg/h are available.

High-performance mixers have intermeshing shafts with 180 to even 8000 litres volumes. In combination with a square mixer hull geometry, these intermeshing paddle shafts gently and efficiently mix all kinds of products, regardless of viscosity or stickiness. It is ideal for pure beef burgers, case ready ground meat, raw sausage meat but also for many other applications.

Paddle mixers

Vacuum mixers

Delicatessen and fine foods mixers

Marinating and Injection

Vacuum Mixing and Tumbling Machines are designed for the use in the all fields of the food production, especially in the processing of meat, poultry and fish processing. They are suitable for the mixing, blending, massaging, marinating and tumbling of all kind of meat, poultry and fish products. The machines captivate with a high user-friendliness, which is achieved by their easy operation and simple cleaning. A huge individualisation of the machines is reached by a wide range of equipment options, in order to achieve the highest possible degree of customer-specific product optimisation.

Intensive massaging technology

Mixing and Tumbling Machines

The processing principle of the IMAX technology is based on classic injection curing by means of hollow needles. This is where know-how regarding needle type, inlet and exit holes and needle stitch pattern plays a decisive role. The brine/emulsion to be injected is carried directly to the product by a system of pumps and pipes. As well as boneless products, bone-in meat, poultry and fish can also be injected.

Manual injectors

IMAX Injection Technology

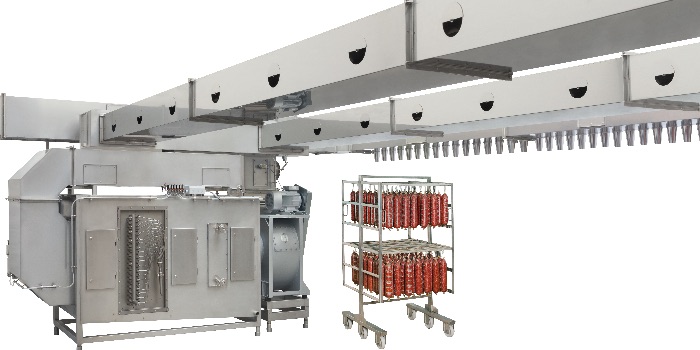

Sausage production

MAJA ice generators for food industry

Flake Ice Machines A deep-frozen metal cylinder, rotating in a water reservoir, guarantees constant ice quality. With each rotation, water freezes on the evaporation drum and then flakes off, leaving the machine as dry-frozen ice.

This system of ice production was developed by MAJA and has proven its reliability for six decades. It is simple, cost-saving and does not require special maintenance.

Developed and brought to perfection by MAJA!

Geneglace flake ice generators

The generators range varies from 500 kg to 50 tons/day. The ice produced is a high quality ice. This wide range may satisfy all customers.

Where your existing refrigeration systems provides spare refrigerating capacity, our ice machines can be offered as stand-alone generators.

In that case we are delivering you the stand alone generator that you has to install near your selected condensing unit or has to be connected to the central refrigeration plant, we confirm in that case the evaporator temperature and the refrigeration capacity you will have to consider for your refrigeration system.