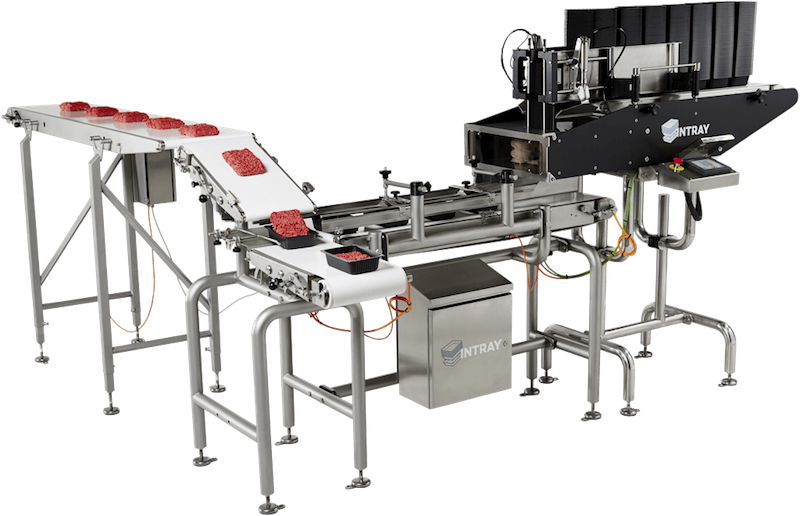

ReeMarket tray sealer

Extremily flexible solution for packaging different portions of fresh food in different tray-format as for vegetable, meat & poultry, fresh fish, grocery and fruits.

Extremily flexible solution for packaging different portions of fresh food in different tray-format as for vegetable, meat & poultry, fresh fish, grocery and fruits.

Number 3 independent processing chambers, able to switch from one to another tray format using the same width of film reel.

No format change-over and an automatic safety film lid positioning makes it user-friendly.

Every mistake is detected and noticed !

Ideal machine for Food packaging Dpt. in the Supermarket.

Machine dose not need any air pressure so that a good saving in energy and in the general maintenance give a good return of the investment.

Technical Data

| Machine height: 1815 mm | Machine width: 930 mm |

| Machine length: 3195 ÷ 6820 mm | Loading conveyor length: 1000 ÷ 4000 mm (reference values for reference) |

| Free loading zone length: 1285 ÷ 3940 mm | Number of trays for loading: 2 ÷ 8 |

| Height of free loading area: 915 – 960 mm | The main movement of the machine: Electromechanical |

| Microprocessor control unit: PLC-Siemens | Control Panel: Digital Control |

| Vacuum pump: 100 – 200 – 300 m3 / h | Power supply: 3 / N / PE AC 400 V 50 Hz |

| Power supply: Min. 4 Kw Max 11 Kw | Compressed air: 4.5 Nl / c. |

| Overall dimensions of a design: Stainless steel | Cycles of the machine: 2-4 cycles / min. (The speed of the cycle depends on: the quality of the material of the tray and the film web, the size of the tray, the product to be packed, and the basic settings of the machine.) |