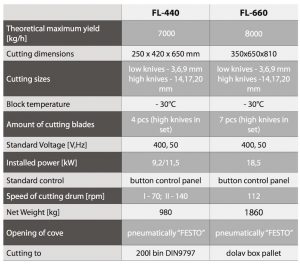

Frozen Block Flaker FL Series

N&N FLAKERS FL series With a cutting area of 350 x 620 x 810 mm (FL-660) these machines are capable of handling any common block size, whether standard EURO-2-blocks or US 60 lbs-blocks (8” x 16” x 24”) and reach capacities, due to the integrated pneumatic feeding arm, of up to 7,0/hr.

N&N FLAKER FL series is designed for the continuous reduction of frozen product at very low temperatures and high volumes whilst maintaining a high quality cut, especially suitable for further processing in bowl choppers, grinders or other downstream equipment. This is achieved by the unique blade design and cutting drum geometry, coupled with the integrated block hold down device and the unique block feeding system

HIGH EFFICIENCY

N&N FLAKERS FL series With a cutting area of 350 x 620 x 810 mm (FL-660) these machines are capable of handling any common block size, whether standard EURO-2-blocks or US 60 lbs-blocks (8” x 16” x 24”) and reach capacities, due to the integrated pneumatic feeding arm, of up to 7,0/hr.

VERSATILITY

N&N Nadratowski worldwide is one of the few suppliers ordering 3 different sizes of blades for its rotating cutters. The raw materials, further processing method and the required pro- duct size, determine the cutting thickness, which can be between 3 and 45 mm.

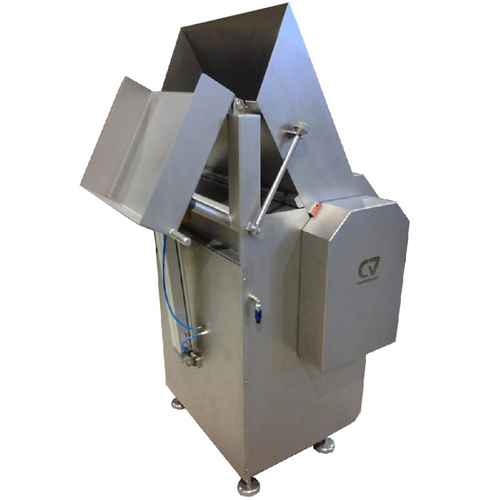

CONSTRUCTED TO MAKE IT EASY TO KEEP IT CLEAN

Due to the fully opening cover over the cutting area and the quick disassembly of the feeding ram, cleaning of the machine is made very easy. All product contact parts are blasted, ground or polished, and the machine body is a completely closed designed, with the control box integrated into the machine frame. Therewith N&N sets the hygiene standard in the industry. Both models are noise protected.

THE HIGHEST QUALITY

N&N Flakers are certified with hygiene and safety regulations as well as with CE mark. N&N Nadratowski company applies a management system EN ISO 9001:2008 in line with the above standard for the following scope: Manufacture and service of machines for food industry. The certification was conducted in accordance with the TUV NORD CERT auditing and certification procedures and is subject to regular surveillance audits.