The all-round vacuum filler RS 110

The all-round vacuum filler RS 110 – outstanding production for innovative small-scale companies.

The new Risco RS 110 continuous all-round vacuum filler has been launched into the market for future oriented small-scale producers.

The all-round vacuum filler RS 110

The all-round vacuum filler RS 110 – outstanding production for innovative small-scale companies.

The new Risco RS 110 continuous all-round vacuum filler has been launched into the market for future oriented small-scale producers.

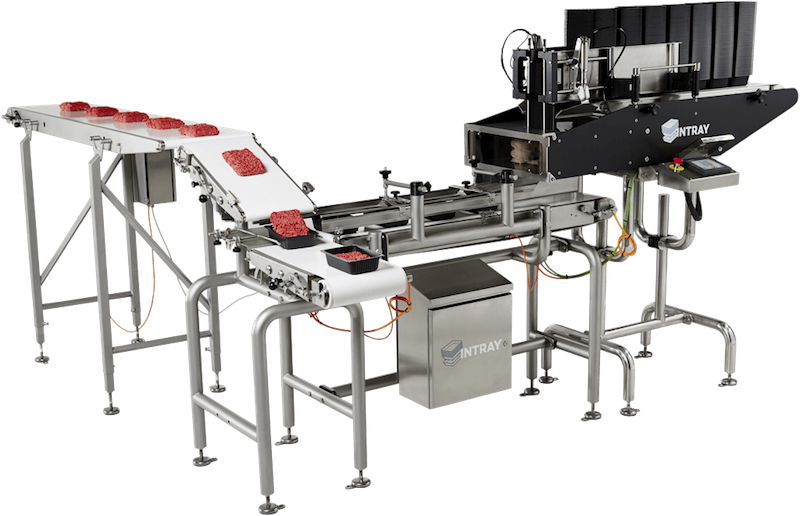

Risco offers the ideal solution for encompassing technology, quality, cost efficiency, innovation in production and thus obtaining accurate superior quality products, including traditional processed items such as sausages, salami, hamburgers or other “classic” items, as well as snacks, delicatessen, finger foods and new trendy foodstuffs.

The entire filling process takes place in a precise and gentle manner, in order to preserve the organoleptic characteristics of the processed food mass, and to guarantee an excellent compaction of the exact portions in the final product.

Main features

· Precise and constant feeding

· Gentle filling with the Risco “Long Life” system

· Immediate and intuitive control

· First-rate performance

· Highest production versatility

· Top level sanitation

· Low maintenance costs

Main points of the modern Risco RS 110 filler

Filling process

· Accurate feeding of the food mass

· Gentle filling process

· Effective vacuum process on the product

· Exact portions (max error +/- 1%)

Production flexibility

· Easy production changes

· Great variety of accessories available

· Simple control-system programming

· Fast cleaning of components

Cost efficiency

· Low wear of moving parts

· Reduced pressure generated in the filling system

· Minimum overall dimensions

· Low consumption servo technology

Advantages for the final product

· Excellent product definition

· Preservation of original characteristics

· Optimum compaction

· Precise portion weights

Technical data

Filling capacity Kg/h 2.800

Max filling pressure bar 35

Portioning speed 25 g 50 g 100 g 200 g

Portion weight gr 5 – 16.000

Hopper capacity lit 70 – 165

Total power installed kW 5

Machine weight Kg 325

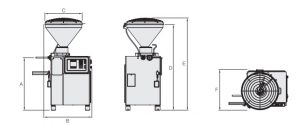

Dimensions mm A B C D E F 980 900 ø 670 1600 1750 750