Portion control meat slicing system FP 240 Maja

Portion control slicing of fresh and frozen meat cuts, without and even with bones, from pork, beef, veal, lamb and turkey.

Wide application range: for all cuts from pork, beef, veal, lamb, poultry; fresh or frozen, without or with bones.

Changeover to other products within seconds.

Minimum changeover and setup times thanks to continuous meat infeed.

High cutting capacity with different types of portion formation.

Maximum yield: Trimming-free portioning of the meat cuts.

The universal portioning solution for applications from A to Z!

Portion control slicing of fresh and frozen meat cuts, without and even with bones, from pork, beef, veal, lamb and turkey.

For the economic production of minute steaks, steaks, schnitzel, beef roulade, pork chops, meat cubes etc.

Dimensions of raw material (dimensions of portioning set): 625 mm (FP 240-6) / 750 mm (FP 240-7)

Cutting capacity: approx. 40 to 240 cuts per min. (gross)

Slice thickness: approx. 2 to 75 mm

Portioning set

Different shapes of infeed mould can be inserted in one portioning set ring, depending on the meat cuts to be portioned. This allows the portioning of different types of products with minimum setup times.

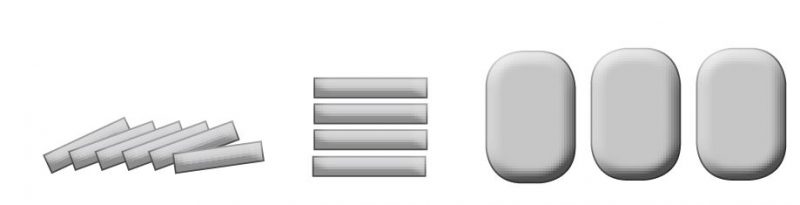

Formations

- Fanned / stacked / single

- Group complementation for completion of the packaging unit

Quality of the cut, weight accuracy & degree of equalization:

- The principle of volumetric portion control allows a very high degree of equalization, as requested by producers of self-service and ready-to-cook meat products.

- Consistent slice thickness and optimum quality of the cut thanks to the use of the special MAJA knife.

- Consistent slice shape.

- Grading: The freshness cut at the beginning and / or final cut at the end are automatically selected and discharged separately. The trimming pieces can be discharged for example into a box.

Several standard portioning programs at choice:

- “Best weight” – weight optimized portioning: As the first portion reaches already the target weight (depending on type of cut), there is only one trimming per meat cut, allowing to reach not only high weight accuracy and consistent portion thickness, but also maximum yield.

- “Best yield” – yield optimized portioning: The raw material is divided into portions of consistent thickness, with close approach to the target weight, allowing to reach maximum yield and to avoid trimmings.

- “Constant thickness” – slice thickness portioning (in millimeters)

- All the portioning programs offer the possibility of a freshness cut at the beginning and/or at the end of the raw material.

- Individual portioning programs can be stored and opened again by the operator at any time.

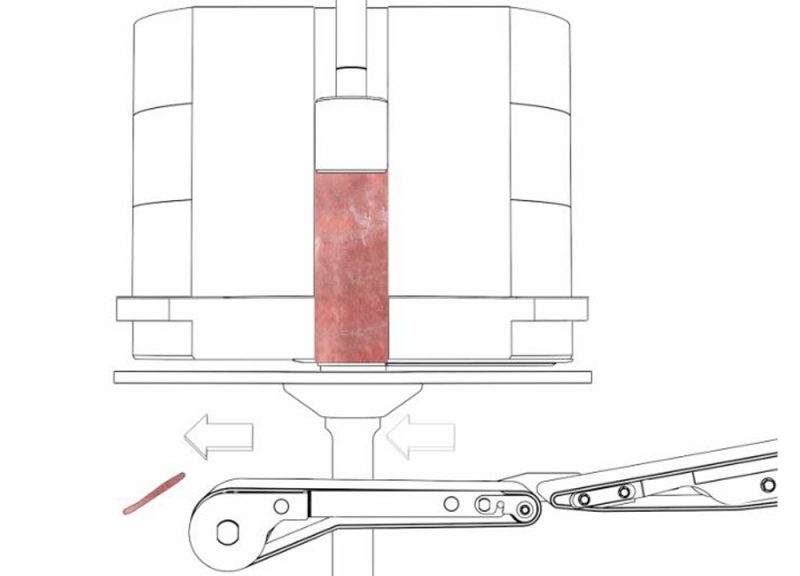

Continuous meat infeed:

- A rotating chamber system allows the continuous infeed of the raw material so that the portioning can take place without interruption. Thus minimum non-productive time.

- High operator safety during infeed of raw material.

Operation & machine features:

- User identification by modern RFID-technology (Radio-Frequency-Identification) with different user keys (chip pict. 1) and security access levels.

- Change of weight category: Fast and easy weight changeover by the operator, within seconds, by menue display (touchscreen display in IP69K)

- Weight correction: Individual and highly flexible, during slicing cycles.

- Changeover and setup times: Very fast product changeover within seconds, without the use of tools.

- Modern servo drive technology: no compressed air required.

Solid construction in hygienic design:

- VA stainless steel up to max. 20 mm.

- Cleaning water can run off easily from chamfered surfaces thus no residues of water, dirt or cleaning agent.

- All machine parts are made from food safe material.

- All calibration set components can be removed for cleaning.

Technical details

- MAJA ref.

- FP 240-6 162-0008

FP 240-7 162-0008-001 - Cutting capacity

- approx. 40 – 240 cuts / min.

- Width

- 997 mm (39.25”)

- Depth

- 1879 mm (73.74”)

- Height

- FP 240-6: 3125 mm (123.0”) / transport height 2100 mm (82.7”’) with hinged down infeed chute)

FP 240-7: 3475 mm (137”) / transport height 2275 mm (90”) - Outlet height

- 869 mm (34.1”)

- Footprint

- 1,9 m²

- Electrical connection

- 17,0 kW

- Weight

- FP 240-6: approx. 1350 kg (2970 lbs)

FP 240-7: approx. 1500 kg (3300 lbs) - Notes

- Current consumption max. 25 A