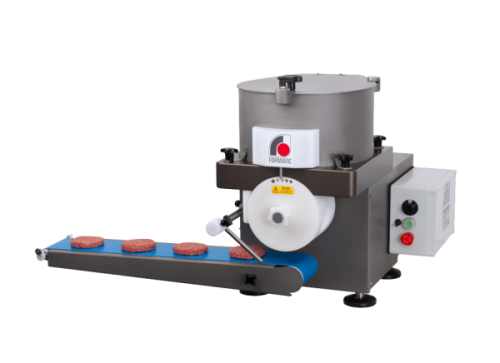

Cutlet Machine R1200

Designed for forming cutlets, hamburgers, fish sticks, potato and flour croquet, cookies and other semi-finished products. It has a drum type of performance. A model with a larger bunker. Productivity – 1200 pcs / h.

Designed for forming cutlets, hamburgers, fish sticks, potato and flour croquet, cookies and other semi-finished products. It has a drum type of performance. A model with a larger bunker. Productivity – 1200 pcs / h.

Model R-1200, the smallest of the entire spectrum presented, is ideal for small production volumes and individual manufacturers.

It combines low productivity and optimal molding capabilities can be used to develop new types of products. Cutlet machines are made of food-resistant, acid-resistant stainless steel and materials certified for contact with food. Each model is equipped with three safety locking devices. The bunker, the forming shop and the conveyor removable that facilitates the cleaning of the car.

Cutlet machines are used in the meat and fish industries, as well as in cooking, can be used both separately and as part of the line. A system of synchronized stainless steel blades gently presses the mixture into the forming hole of the drum. Formed semi-finished product is pushed by the piston to the discharge conveyor and goes further along the production line.

The machine is able to produce products of almost any shape (fish, sticks, rectangles, squares, chicken breast, ellipses, etc.), provided that it does not exceed the maximum sizes indicated below.

To achieve the exact desired weight of the product, the depth of the forming hole is adjustable from 3 to 24 mm in a standard drum, and from 3 to 34 mm in a special drum.

Technical Data

| Overall dimensions | 700mmх600mmх640mm |

| Installation | Table |

| Weight | 75kg |

| Power supply | 220V |

| Connection | Electrical |

| Power | 0,37 kW |