Scalding and Dehairing Machines, Pre and Subsequent Cleaning

Pre-Cleaning with the Renner Brushing washing machines. Thoroughly cleans the carcass soiled with dirt and blood. The scalding water is thereby less soiled.

Pre-Cleaning with the Renner Brushing washing machines. Thoroughly cleans the carcass soiled with dirt and blood. The scalding water is thereby less soiled.

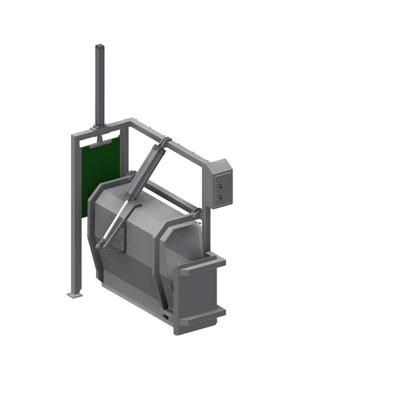

Scalding with the Renner Paddle Wheel Tanks is a process where the pig is automatically immersed into a tank with scalding water at approx. 60°C.

De-hairing is carried out with a nonsynchronous de-hairing machine by Renner. These machines by Renner are designed for the de-hairing of 40-200 pigs per hour.

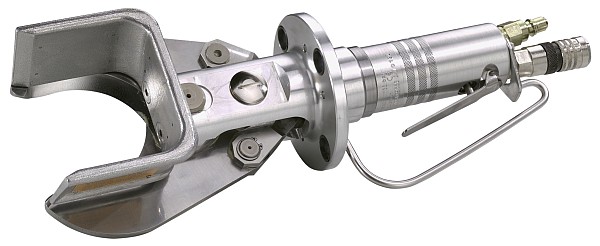

The Subsequent cleaning of the pigs is carried out with drying whips, furnaces, wet whips and decontamination furnaces by Renner.

Renner Combined Scalding– and De-hairing Machines for the Trade. The machines are designed for a capacity of up to 15 pigs per hour.

The Renner Scalding and De-Hairing Machines are developed for a capacity of up to 200 pigs per hour. Dependent on the weights of the pigs, 1 or 2 carcasses are processed in the robust Renner Scalding and De-Hairing Machine.

The Renner Paddle Wheel Tank, which is equipped with an intensive water circulation process and precise temperature control provides for a perfect result. Renner Paddle Wheel Tanks are heated with steam.

Heat exchangers are optionally available as well as electric heating systems for smaller capacities. As an option, the de-hairing machines by Renner can be equipped with a singeing device working with liquefied petroleum gas or natural gas.

The last remaining bristles are removed by singeing in the machine. Optionally, a conveyor system can be installed below the de-hairing roller to evacuate the bristles.