Horizontal packing machine BHL160

Horizontal packing machine BHL160 – BHL series horizontal packaging machines with linear arrangement are designed for production of flat bags of thermally welded packaging material roll. The machine may be used for packaging of small piece, granulated, quickly flowing, slowly flowing, pasty and liquid products. The machine allows packaging up to three components in one bag.

Horizontal packing machine BHL160

Horizontal packing machine BHL160 – BHL series horizontal packaging machines with linear arrangement are designed for production of flat bags of thermally welded packaging material roll. The machine may be used for packaging of small piece, granulated, quickly flowing, slowly flowing, pasty and liquid products. The machine allows packaging up to three components in one bag.

The result is a filled and closed bag or double-bag with three or four sides welded. Bags filled with product leave the machine on a slide or an outfeed conveyor for further handling.

The machine has an electromechanical drive. It has a step operating cycle. Machine control is performed by the control system allowing easy setting of machine parameters.

Basic machine specifications

Welding method: thermal.

Packed product: piece.

Controls: mechanical/electronic, according to the type of the machine electronic programmable controls allowing continuous changing of bag length, machine output, goods batch advance with the unlimited possibility of configuration setup and reporting of error messages on the control panel. Archiving 100 machine programs.

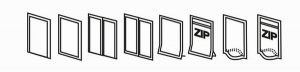

Packaging material types: flat bag 3-4 welds, double-bag, triple-bad, doypack +zipper, flat bag +zipper, and bags of various other formed shapes.

Machine drive system: decentralized, electro-mechanical, combined with pneumatic.

Working cycle: discontinuous.

Machine version: varnished, stainless.

Machine packed into these types of bags

Basic types of BHL series machines – output parameters

| Machine type | BHL160simplex | BHL160duplex |

|---|---|---|

| Machine output | Up to 100 bags/min | Up to 200 bags/min |

Possible equipment of the packaging machine:

- Automatic dosing machines according to the type of the product,

- printing equipment,

- exhaust systems,

- bag die cutting,

- Euro-opening,

- application of zippers and enclosures,

- various types of cutting tools,

- sorting, counting systems,

- conveyor systems.

Technical parameters

| Bag dimensions –simplex (width*height) | Min. 50 * 60 mm |

|---|---|

| Max. 160 * 190 mm | |

| Bag dimension –duplex (width*height) | Min. 50 + 50 * 60 mm |

| Max. 80 + 80 * 190 mm | |

| Machine dimensions – Width | 900 mm |

| Machine dimensions – Height | 1725 mm |

| Machine dimensions – Length | 3520 (4250) mm |

| Machine weight | 1200 kg |