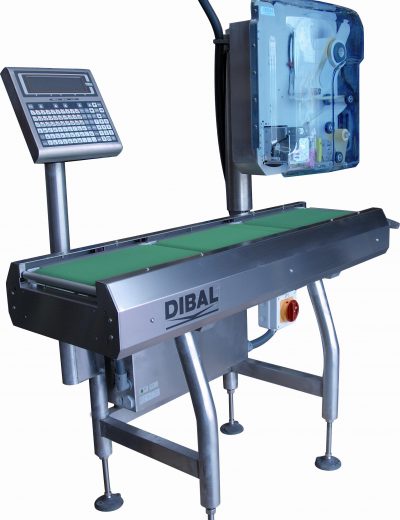

Automatic weighing and labelling LS-4000

High speed automatic weighing and labelling system. Dynamic weighing.

High speed automatic weighing and labelling system. Dynamic weighing.

– AISI 304 stainless steel and anodized aluminium structure.

– Quick change of the conveyors.

– Easy cleaning.

– 3 conveyors: entry, weighing and labelling.

– Separation conveyor (optional).

– Weighing conveyors of L350 x W200, L600 x W200, L400 x W280, L600 x W280, L400 x W400 and L600 x W400 mm.*

* Other dimensions, consult us.

– Up to 100 labels/minute in weighing and top labelling.*

– Up to 40 labels/minute in weighing and under labelling.*

– Up to 120 labels/minute in weight only.*

For higher operating speed, consult us.

– 8.000 PLUs.

– Control console with keyboard and graphic LCD display.

– 15” touchscreen, optional.

* Real performance will depend on the weight and size of the package, the regular infeed of packages, the dimension and quality of the label, and MID conditions (“green M”).

Dynamic (programmable as static if necessary).

– 6 kg/2 g or 10 kg/5 g with weighing conveyor up to L400 x W400 mm.

– 15 kg/5 g, 20 kg/10 g, 30 kg/10 g, 40 kg/20 g or 60 kg/20 g with weighing conveyor up to L600 x W500 mm.

– 3 kg /1 g and others, consult us.

– Direct thermal printing or thermo-transfer.

– 3” or 4” printer.

– Top label: from W30 x L35 mm, up to W80 x L100 mm (3”) (or up to W102 x L150 mm (4”)).

– Bottom label: from W30 x L55 mm, up to W80 x L100 mm (3”) (or up to W102 x L150 mm (4”)).

– Labels of totals in the same LS-4000, or in Dibal LP-3000 printer.

– Long range printhead.

– Top label application by “air-jet” system or by pneumatic piston.

– Bottom label application by contact.

– Monitored adjustment of the height of the top labeller.

– Top, under, front, side or corner (L) labelling.

– Barcodes: EAN-8, EAN-13, EAN-128, CODE 128, ITF-14, GS1 DATAMATRIX, and GS1 DATABAR.

– Generic traceability.

– UE-1169/2011 Regulation, concerning consumer information on foodstuffs.

– Ethernet TCP/IP.

– RS-232.

– Wi-Fi, optional.

– Dibal LP-3000 manual labeller.

– Dibal GS-3000 batch collector (+ LP-3000).

– Dibal MD-5000 metal detectors.

– Etc.

– Artificial vision camera. New!

– Barcodes reader.

– Etc.

Dibal Windows software:

– RMS: to configure the machine and management of production data. LBS for data backup.

– DLD: Graphic design of labels.