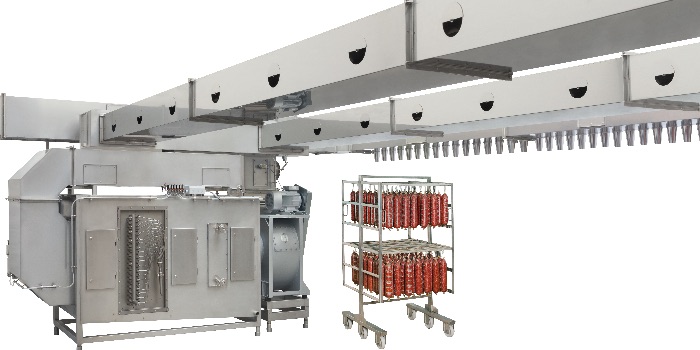

AIRMASTER® UKF SmartSmoker space-saving universal smokehouse

The AIRMASTER® UKF SmartSmoker has already made a name for itself in practice. This extremely space-saving universal unit impresses with a friction smoke generator integrated into the gate with a unique, low-noise and low-vibration SmartSmoker conical friction wheel. The units of the AIRMASTER® UKF series are totally multifunctional and therefore suitable for various applications. They are characterised by the highest performance and uncompromising quality – 100 % Made in Germany.

- Highest air volumes

- Short, energy-efficient processes

- Maximum yield

- Greatest possible consistency

- Best product quality

- High load capacity

- Tightly welded chamber modules

- Fully stainless steel 1.4301

- Mineral full insulation

- No uninsulated housing parts

- Small width and height

- Low-maintenance and reliable

- Particular stability and service life

- Made in Germany

The core of the AIRMASTER® UKF is formed by the SmartSmoker integrated into the chamber doors, a unique friction smoke generator with the patented conical friction wheel. It is low-wearing, friction noises and vibrations are considerably reduced and it guarantees a strong, natural generation of smoke. UKF universal units can be supplied as a one-trolley unit in various sizes or as a two-trolley unit. Special sizes are possible upon request.

An artisan company demands a large degree of versatility from its smoker. Apart from the usual application possibilities,such as reddening, drying, smoking, cooking, hot-cooking/baking, a universal unit is often also used in the production of raw and dried sausages, as well as raw cured products and for climatic smoking. The AIRMASTER® UKF can be equipped with the required functions for all desired areas of use.

Naturally there is integrated, fully-automatic CIP cleaning. Many available equipment options ensure that you can configure your unit precisely according to your specific requirements.

Unit Description

The design of the AIRMASTER® UKF units is based on a modular kit system. Components such as controls, smoke generator and cleaning system can be arranged individually according to your desires or spatial requirements.

Depending on the unit size, the chamber housing of AIRMASTER® UKF comprises one or more chamber modules. Each chamber module is very sturdy and is made of 100 % chromium-nickel steel, material no. 1.4301, and is welded to be smoke and steam-tight. Mineral full insulation (temperature-resistant up to +650°C) protects against heat losses. Importance was attached to avoiding thermal bridges in the construction of the unit.

The top section of each chamber module contains the air preparation unit with ventilator, heat battery and optional cooling. The greatest advantage of this modular system compared to systems with a central unit is that each chamber trolley is supplied exactly the same with air, heat or cold energy and therefore absolute consistency is also ensured from trolley to trolley.

Added-value from modular design:

- Same results in all trolleys

- Tightly welded chamber modules

- Fully stainless steel 1.4301

- Mineral full insulation

- No uninsulated housing parts

- Small width and height

- Low-maintenance and reliable

- Particular stability and service life

The AIRMASTER® UKF works with the proven vertical airflow principle. The air, which has been treated in the upper section, flows around the products from bottom to top. A newly developed blowing system guarantees that the products are treated consistently and in the shortest time in all positions of the chamber trolley. Compared to the competition, REICH systems work with particularly strong ventilators, thereby achieving more output and efficiency.

More output:

- Highest air volumes

- Short, energy-efficient processes

- Maximum yield

- Greatest possible consistency

- Best product quality

- High load capacity

- Process temperatures up to + 200 °C

Only high quality products from German brand manufacturers are used for all heavily used parts such as motors, ventilator impellers,valves, cylinders, etc. In this way we ensure that the highest quality and reliability are achieved in detail.

Each AIRMASTER® has a robust chamber floor. Packing with heavily loaded chamber trolleys is not a problem. In a special version, packing is also possible using forklifts. The floor construction is kept very flat and has a sloped entrance. The substructure of the chamber floor is reinforced in the direction of travel with strong U profiles.

All AIRMASTER® systems are fitted with one or more fully insulated, stable block doors, which are sealed against the chamber housing all the way around with a silicon seal. The door hinges are made entirely from chromium-nickel steel for the high demands of seal and long service life. The doorstop can be fitted left or right as required.

For fresh air, exhaust, and smoke flaps, tight-closing, metallic folding flaps or silicon rubber rotating flaps are used. These flaps have multifunctional positions for controlling the amount of the volume flows.

The systems can be fitted either with electric heating, steam heating, gas or oil-burner heating.

Technical data

| AIRMASTER® UKF | 1200 | 1800 | 2000 | 2100 | 2500 |

|---|---|---|---|---|---|

| Number of trolleys | 1 | 1 | 1 | 1 | 1 |

| Chamber length [mm] | 900 | 900 | 900 | 1050 | 1200 |

| Chamber width [mm] | 1120 | 1120 | 1350 | 1350 | 1450 |

| Chamber height [mm] | 1720 | 2200 | 2200 | 2400 | 2630 |

| Minimum room height [mm] | 2120 | 2600 | 2600 | 2800 | 3150 |

| Chamber height oil/gas [mm] | a. Anfr. | a. Anfr. | 2200 | 2400 | 2630 |

| Minimum room height o/g [mm] | a. Anfr. | a. Anfr. | 2600 | 2800 | 3150 |