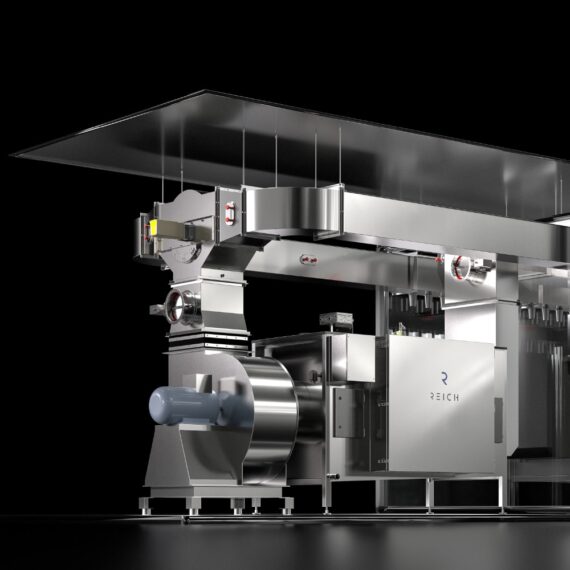

AIRMASTER® ATA ClimaStar – defrosting of meat, fish and poultry

REICH ATA ClimaStar defrosting systems stand out for their economical operation and their gentle product defrosting. From thin, frozen products without packaging to thick, packaged frozen blocks – with REICH ATA systems you can handle the specific requirements of any product and any process.

The REICH ATA ClimaStar defrosting system is renowned for its cost-effective operation and delicate approach to thawing products. It excels in defrosting a wide range of frozen items, from slender, unpackaged goods to hefty, packaged frozen blocks, meeting the diverse demands of various products and processes with ease.

Key highlights include:

– Efficient and uniform defrosting ensuring top-notch product quality and hygiene

– Minimal weight reduction during defrosting

– Exceptionally low-energy consumption due to state-of-the-art smart process management

– Product-friendly, highly effective, and economical design

– Entirely constructed from premium 1.4301 stainless steel

– Proudly manufactured in Germany

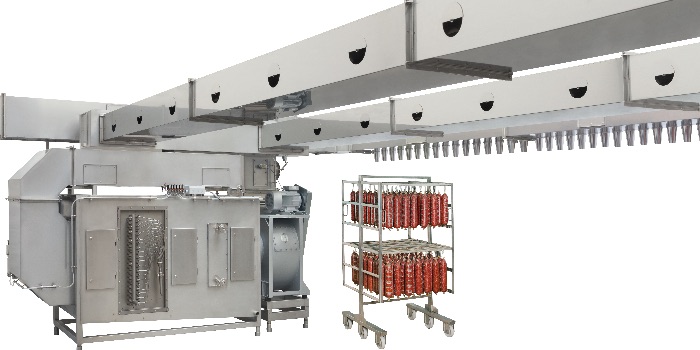

The system employs an air-based method for thawing, ensuring swift and consistent results. It’s designed for hygiene and significantly reduces product loss caused by dripping. Additionally, the system can be set to a specific ‘cold storage’ mode post-defrosting, preserving the coolness of thawed items for an extended period.

The defrosting process, crafted by REICH, utilizes advanced intelligent process control based on the principles of physics:

Initially, the defrosting chamber’s humidity is increased. This moist air then cools upon contact with the frozen product, leading to the immediate condensation and crystallization of moisture on the product’s surface. This phase change releases heat, gradually warming the product. The chamber is then heated, melting the newly-formed ice layer. This cycle continues until the product achieves the desired surface temperature, after which the system enters a pause mode, halting fan, heating, and humidification, until the ideal core temperature is attained.

Throughout this process, the product’s surface temperature remains low, ensuring superior hygiene and safety against bacterial growth, thereby maintaining the product’s quality.

In its smart automatic mode, the system requires minimal input from the operator, such as initial room temperature, maximum product surface temperature, and desired core temperature. The system utilizes two Pt-100 temperature sensors to monitor the product’s surface and core temperatures throughout the process.

For thinner products, where surface temperature sensors can’t be used, the system relies on the core temperature sensor and a preset process duration tailored to the product.

The system is controlled via a user-friendly touch screen with a vivid TFT display and advanced capacitive touch technology. It offers multiple interfaces for seamless data transfer and integration with REICH’s MasterControl visualization program. This program enables detailed monitoring and logging of temperature and moisture trends, ensuring stringent quality control in line with HACCP and IFS standards (ISO 9000).

Furthermore, the REICH RemoteControl system offers remote operation capabilities, allowing users to manage the system and MasterControl program from any location with internet access.

All climatic maturing units are designed individually for your requirements and products. For this, the performance data and the unit geometry are calculated precisely.