Frontmatec to focus on Digitization, Automation and Integration at IFFA

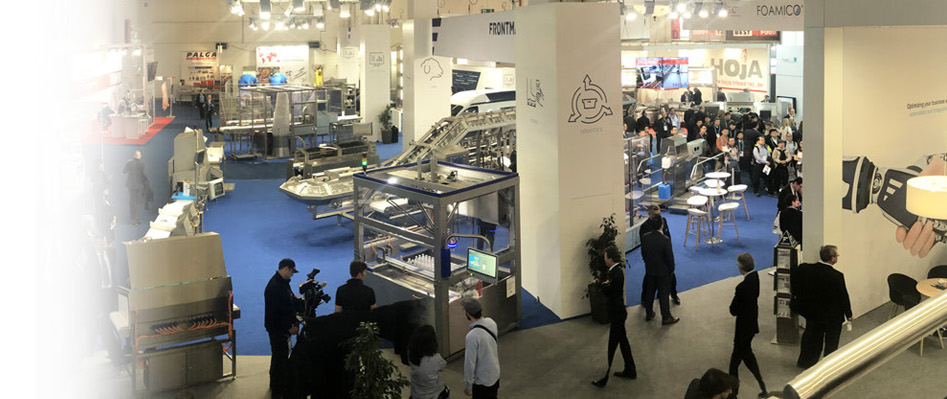

Leading global supplier of customized equipment, solutions, and software for the red meat industry, Frontmatec, participate at IFFA 2022 with a range of new innovative solutions.

Held every three years in Frankfurt, Germany, IFFA is the most important global trade fair for the international meat industry. It is the only trade fair in the world that covers all aspects of meat production and brings together companies from around the world to present their innovations and technologies.

Frontmatec offer, with locations in Europe, America, and Asia, complete concepts and turnkey solutions for the international food industry and is especially well known for its high-quality systems for the entire value chain of the meat industry – from carcass grading, slaughter lines, cutting and deboning lines, hygiene systems and control systems to logistics and packaging, all unique solutions, that create considerable value for customers.

Visitors to the Frontmatec booth will be presented with the latest equipment and solutions from the Frontmatec group. On display will be our latest innovations, including a range of robots for both dressing line and cutting & deboning, a new beef grading instrument, and new deboning and trimming concepts. ITEC hygiene solutions will be showcasing their new Smart Control for their hygiene systems while our Service Solutions will be demonstrating the Remote Eye support service at both.

Digitization, Automation, and Integration

The latest years have shown that new technologies and faster networks have pushed meat processors to the next level of data acquisition and analysis. Leading this transformation, Frontmatec will focus its presence at IFFA on bridging the data acquisition and analysis with the equipment solutions.

Frontmatec will present its newest software solution, Frontmatec BIS (Business Intelligence Systems). Frontmatec BIS is a digital ecosystem for the transformation of data for many different data sources to ensure data-driven operations. Frontmatec BIS allows users to use fact-based knowledge for critical decision-making regarding food safety, traceability, and overall effectiveness in meat production.

At the Frontmatec booth, it is also possible to experience the food processing software, GO, which will cover key production process areas for data collection across the production floor as well as device and line monitoring covering supervisory control and data acquisition.

The GO platform for traceability ensures constant, direct access to valuable information that can reduce losses on expired products and optimize the product age level. It also provides direct real production time data which is crucial for modern meat processors to optimize ordering, packaging, and palletizing processes.

Advances in automated carcass grading

Frontmatec has with the in-line AutoFomTM and the handheld Fat-O-Meat’erTM instruments defined how pig carcass grading is done in modern slaughterhouses worldwide. These industry-defining instruments are now being matched with solutions for the beef industry. On display at IFFA, will be the innovative Beef Classification Center 3 – BCC-3TM – a step-change in the accuracy and the wealth of useful information available with automated in-line carcass grading. Using advanced multi-view stereo imaging it creates full 3D images of the split carcass and produces accurate EUROP grading scores and weight estimates of the primal and commercial cuts. Information that allows the slaughterhouse to maximize the economic value it gets out of each carcass.

Launch of Q-FOMTM Beef for objective assessment of meat quality

A new standard for accuracy and reliability in meat quality grading will be launched at IFFA. Q-FOMTM Beef is a sophisticated, hand-held grading camera that is transforming the way meat quality is assessed. Set to replace subjective grading by the eye of commercial graders, the industry will now get access to reliable and consistent measurements of beef cuts’ marbling, meat color, fat color, eye muscle area, and other traditional parameters important to the industry. With a bespoke GOSystemsTM module for Q-FOMTM Beef the complete integration to the plant’s production planning is secured.

Let the robots do the work

The unrivaled broad program of robots covering dressing lines, overcutting, and deboning to packaging helps reduce labor, increase quality and yield. At IFFA, our experts from AIRA and Frontmatec will offer advice on robotic solutions and where best to automate in the process line. Several robot solutions will be demonstrated, including the world’s only circular blade Cattle Splitting Saw. AIRA will also reveal their new Leaf Lard Remover robot for the first time, which will take the strain from one of the most tedious operations on the dressing line.

For the cut floor, the Frontmatec Robotic Chine Bone Saw is on display in a completely new configuration. Besides labor-saving, the possibility to create recipes with parameters suitable for different customer wishes or changes in raw material provides considerable efficiency and yield gains.

One of the key goals within the meat industry is improved ergonomics and Frontmatec continuously develops automatic solutions to reach this goal! The latest state-of-the-art solution is a high-speed Pork Single Rib Puller with the automatic pulling of single ribs with robots, removing one of the most straining working tasks within the pork deboning industry.

The unique Frontmatec 2D Loin trimmer has been updated with ultrasound to measure and classify loins with bones individually. Loins without bones are measured and classified by the use of a probe. The input from the probe and ultrasound is also used to adjust the cutting knives and pressure wheels for the most optimal cut according to the selected product types, thus greatly improving yield and reducing labor costs.

Optimizing and gaining higher yields is a constant goal for the meat industry. The Frontmatec Q-line system can help improve the production quality and yield, as it is designed for trimming high-value products from beef as well as pork. All by-products from the trimming process are collected in trays, giving complete batch control by automatic weighing. For the Q-line, Frontmatec has developed 3 different software versions optimized for the required type of production.

The popular ITEC Star Clean walk-through hygiene station for sole and hand hygiene – presents itself at the Frontmatec booth with a new future-oriented Hygiene 4.0 feature: Smart Control – Central visualization and diagnosis of machine states to optimize operational processes. Smart Control provides a precise overview of necessary and upcoming service and maintenance work, enables error analyses via remote maintenance, and provides usage and consumption data at the push of a button. It cannot only be integrated into a hygiene station but in all units that are part of the operational hygiene process.

With Covid in mind, several fully operational ITEC hand disinfectant units will also be on display on the booth to demonstrate the superior built quality that is capable to operate in the harshest type of environments.

Be a step ahead with Frontmatec service solutions.

Key to your success is high production performance, increased uptime, and yield improvement, which is why Frontmatec service specialists are continuously developing concepts and solutions to increase your profit throughout the complete value chain.

At IFFA, you will meet our Service Team, and let you experience the latest service solution,

real-time remote support, and show how only a few minutes can increase your profit and maximize your uptime. The Service Team will also present a campaign where you can win a nice prize.

Representatives from every business unit of the group, including the newly acquired ASUAN from Uruguay, will be present at the Frontmatec booth.